Our CNC machining capabilities include a wide range of services, from aluminum CNC machining parts to high precision machined parts for medical devices,automation, automotive, aerospace ,Oil & gas and semiconductor applications. As a rapid prototype service and prototype shop, we specialize in rapid prototype machining , providing precision machining service for small quantity CNC machining and small parts fabrication.

With our expertise in oil&gas CNC machining and machining inconel 718, we are able to deliver precision CNC parts and precision CNC machined parts that meet the highest standards of quality and performance. As one of the top CNC prototyping China suppliers, we offer CNC machining on demand and rapid prototyping suppliers to help you bring your designs to life quickly and cost-effectively.

As a CNC machining parts supplier and CNC machining parts manufacturer, we are committed to delivering the highest quality CNC machining parts China has to offer. Whether you need small parts machining for semiconductor applications or high precision machined parts for medical devices, we have the experience and expertise to meet your needs.

So if you're looking for a reliable CNC machining parts supplier or Chinese prototype manufacturers, look no further than our CNC machining capabilities. Contact us today to learn more about our rapid prototype machined parts and CNC machining small parts services.

With our expertise in oil&gas CNC machining and machining inconel 718, we are able to deliver precision CNC parts and precision CNC machined parts that meet the highest standards of quality and performance. As one of the top CNC prototyping China suppliers, we offer CNC machining on demand and rapid prototyping suppliers to help you bring your designs to life quickly and cost-effectively.

What is CNC Machining?

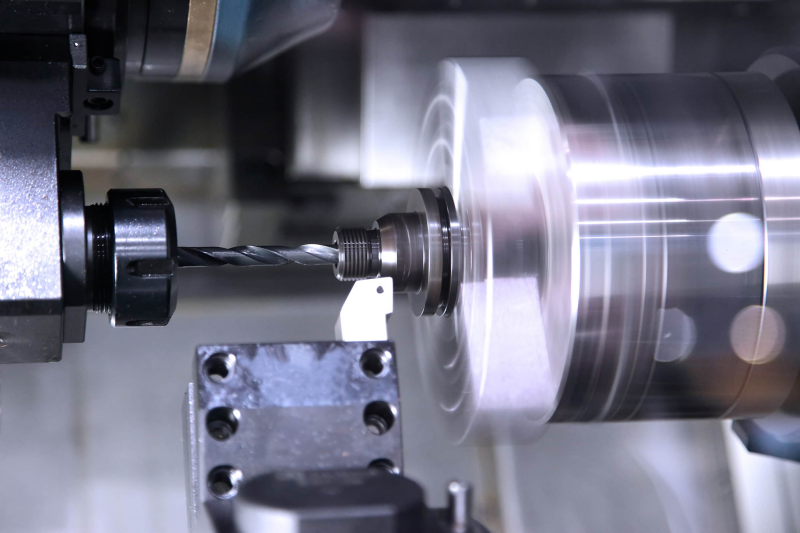

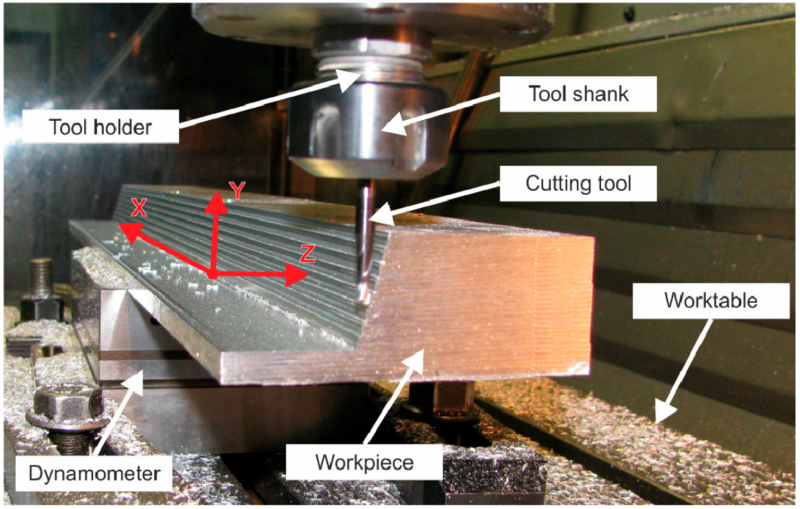

CNC machining is a manufacturing process that uses computer-controlled machines to remove material from a workpiece to create a final product. is a widely used manufacturing process that uses automated, high-speed cutting tools to form designs from metal or plastic stock. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. This process is commonly used to produce machine parts, lathe parts, and other components for various industries, including aerospace, medical, and automotive.

CNC machining services are highly versatile and can be used to work with a wide range of materials, including PEEK, PTFE, aluminum, Steel,inconel 718, and Teflon. This allows for the creation of highly precise and complex parts, making CNC machining an ideal choice for prototyping, rapid prototyping, and rapid manufacturing.

CNC machine shops and machining manufacturers use a variety of techniques to create highly precise parts, including EDM machining and other advanced manufacturing processes. These techniques allow for the creation of highly complex geometries and shapes, ensuring that the final product meets the exact specifications of the customer.

Anodized aluminum is a popular material for CNC machining, as it provides a durable and corrosion-resistant surface. Aluminum anodizing is a process used to create anodized aluminum, which involves creating an oxide layer on the surface of the aluminum. This process helps to improve the durability of the material and enhances its appearance.

Overall, CNC machining offers a highly efficient and precise method for creating machine parts and other components. Whether you need prototyping services or require rapid manufacturing of complex components, CNC machining shops can provide the expertise and equipment needed to bring your designs to life.

Metal Machined Parts Manufacturer in China

At LaiRun machining, we provide quick-turn custom CNC machining services for your specific applications across a wide variety of industries, whatever you need rapid prototypes, high-volume machined parts, or affordable small batches. Our highly skilled engineers and machine shop employees can provide the most effective and cost-efficient solutions for your projects, 20 years of experience and the fully equipped machine shop allow us to produce high-quality functional CNC metal machining components and assemblies with high efficiency and productivity. We have 3Axis, 4Axis, and 5Axis machining centers, as well as other high-performance tools and inspection tools, run for manufacturing and measurement. If you are looking for a metal machining company for both small and large-sized CNC metal parts, LaiRun is one of the best choices! You’ll have a lot of metal materials to choose from, aluminum, steel, stainless steel, brass, copper, bronze, titanium, etc., and various grades of these metals are provided to achieve the highest standards of required products.

Why Choose LAIRUN CNC Machining Services as your reliable China supplier?

1.RFQ response within 24 hours.

2.Fastest delivery is 1 day.Quick turnarounds and fast delivery as your target project schedule.

3.High quality control by precision machinery and achieve ISO:2015 quality control system.

4. Production equipment and testing equipment from Germany, Japan, Korea and Taiwan.

5. Company owner and management team has working experience in Fortune 500.

6.Professional and experienced engineering ability when facing challenge parts.Engineering team are Bachelor degree or above in mechanical major.

7. A wide selection of popular materials of metal and plastic for CNC machining components.Located in Dongguan city, the manufacturing capital of the world, with complete supply chain from material to surface treatment.

8.ERP system management.High flexibility in production dimensions, quantities, complexity, and technologies.