What is CNC Milling?

CNC milling is a manufacturing process used to produce custom-designed parts from various materials such as aluminum, steel, and plastics. The process employs computer-controlled machines to create complex parts that are difficult to produce using traditional machining techniques. CNC milling machines are operated by computer software that controls the movement of cutting tools, enabling them to remove material from a workpiece to create the desired shape and size.

CNC milling offers several advantages over traditional milling methods. It is faster, more precise, and capable of producing complex geometries that are difficult to create using manual or conventional machines. The use of computer-aided design (CAD) software allows designers to create highly detailed models of parts that can be easily translated into machine code for the CNC milling machine to follow.

CNC milling machines are highly versatile and can be used to produce a wide range of parts, from simple brackets to complex components for aerospace and medical applications. They can be used to produce parts in small quantities, as well as large-scale production runs.

3-axis and 3+2-axis CNC milling

3-axis and 3+2 axis CNC milling machines have the lowest start-up machining costs. They are used to produce parts with relatively simple geometries.

Maximum part size for 3-axis and 3+2-axis CNC milling

|

Size |

Metric units |

Imperial units |

| Max. part size for soft metals [1] & plastics | 2000 x 1500 x 200 mm 1500 x 800 x 500 mm |

78.7 x 59.0 x 7.8 in 59.0 x 31.4 x 27.5 in |

| Max. part for hard metals [2] | 1200 x 800 x 500 mm | 47.2 x 31.4 x 19.6 in |

| Min. feature size | Ø 0.50 mm | Ø 0.019 in |

[1] : Aluminum, copper & brass

[2] : Stainless steel, tool steel, alloy steel & mild steel

High-Quality Rapid CNC Milling Service

High-quality rapid CNC milling service is a manufacturing process that offers customers quick turnaround times for their custom parts. The process uses computer-controlled machines to produce highly accurate parts from various materials such as aluminum, steel, and plastics.

At our CNC machine shop, we specialize in providing high-quality rapid CNC milling services to our customers. Our state-of-the-art machines are capable of producing complex parts with exceptional precision and speed, making us the go-to source for customers in need of quick turnaround times.

We work with a variety of materials, including anodized aluminum and PTFE, and can provide a range of finishes, including aluminum anodizing. Our rapid prototyping services allow us to create and test parts quickly, ensuring that our customers receive the highest quality products in the shortest amount of time possible.

How CNC Milling Works

CNC milling works by using computer-controlled machines to remove material from a workpiece to create a specific shape or design. The process involves a range of cutting tools that are used to remove material from the workpiece to create the desired shape and size.

The CNC milling machine is operated by computer software that controls the movement of the cutting tools. The software reads the design specifications of the part and translates them into machine code that the CNC milling machine follows. The cutting tools move along multiple axes, allowing them to produce complex geometries and shapes.

The CNC milling process can be used to create parts from a variety of materials, including aluminum, steel, and plastics. The process is highly accurate and capable of producing parts with tight tolerances, making it ideal for the production of complex components for aerospace and medical applications.

Types of CNC Mills

3-Axis

The most widely used type of CNC milling machine. The full use of the X, Y, and Z directions makes a 3 Axis CNC mill useful for a wide variety of work.

4-Axis

This type of router allows the machine to rotate on a vertical axis, moving the workpiece to introduce more continuous machining.

5-Axis

These machines have three traditional axes as well as two additional rotary axes. A 5-axis CNC router is, therefore, able to machine 5 sides of a workpiece at in one machine without having to remove the workpiece and reset. The workpiece rotates, and the spindle head is able to also move around the piece. These are larger and more expensive.

There are several surface treatments that can be used for CNC machined aluminum parts. The type of treatment used will depend on the specific requirements of the part and the desired finish. Here are some common surface treatments for CNC machined aluminum parts:

Other Benefits Of CNC Mill Machining Processes

CNC milling machines are built for precise manufacturing and repeatability which makes them perfect for rapid prototyping and low-to-high volume production runs. CNC mills can also work with a variety of materials from basic aluminum and plastics to more exotic ones like titanium — making them the ideal machine for almost any job.

Available materials for CNC machining

Here is a list of our standard CNC machining materials available in our machine shop.

| Aluminum | Stainless steel | Mild, Alloy & Tool steel | Other metal |

| Aluminum 6061-T6 /3.3211 | SUS303 /1.4305 | Mild steel 1018 | Brass C360 |

| Aluminum 6082 /3.2315 | SUS304L /1.4306 | Copper C101 | |

| Aluminum 7075-T6 /3.4365 | 316L /1.4404 | Mild steel 1045 | Copper C110 |

| Aluminum 5083 /3.3547 | 2205 Duplex | Alloy steel 1215 | Titanium Grade 1 |

| Aluminum 5052 /3.3523 | Stainless Steel 17-4 | Mild steel A36 | Titanium Grade 2 |

| Aluminum 7050-T7451 | Stainless Steel 15-5 | Alloy steel 4130 | Invar |

| Aluminum 2014 | Stainless Steel 416 | Alloy steel 4140 /1.7225 | Inconel 718 |

| Aluminum 2017 | Stainless Steel 420 /1.4028 | Alloy steel 4340 | Magnesium AZ31B |

| Aluminum 2024-T3 | Stainless Steel 430 /1.4104 | Tool Steel A2 | Brass C260 |

| Aluminum 6063-T5 / | Stainless Steel 440C /1.4112 | Tool Steel A3 | |

| Aluminum A380 | Stainless Steel 301 | Tool Steel D2 /1.2379 | |

| Aluminum MIC 6 | Tool Steel S7 | ||

| Tool Steel H13 |

CNC Plastics

| Plastics | Reinforced Plastic |

| ABS | Garolite G-10 |

| Polypropylene (PP) | Polypropylene (PP) 30%GF |

| Nylon 6 (PA6 /PA66) | Nylon 30%GF |

| Delrin (POM-H) | FR-4 |

| Acetal (POM-C) | PMMA (Acrylic) |

| PVC | PEEK |

| HDPE | |

| UHMW PE | |

| Polycarbonate (PC) | |

| PET | |

| PTFE (Teflon) |

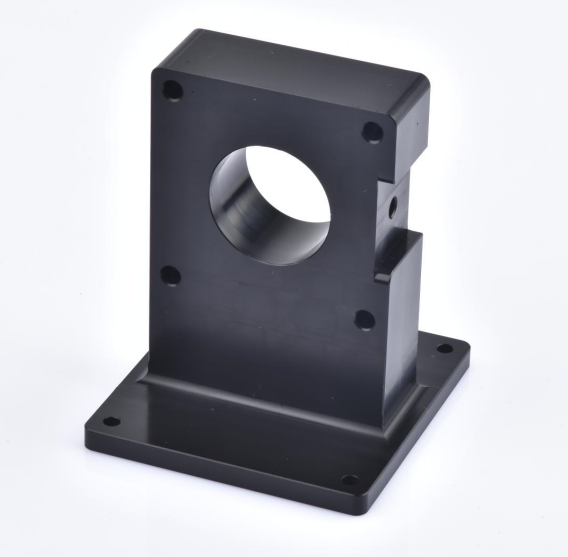

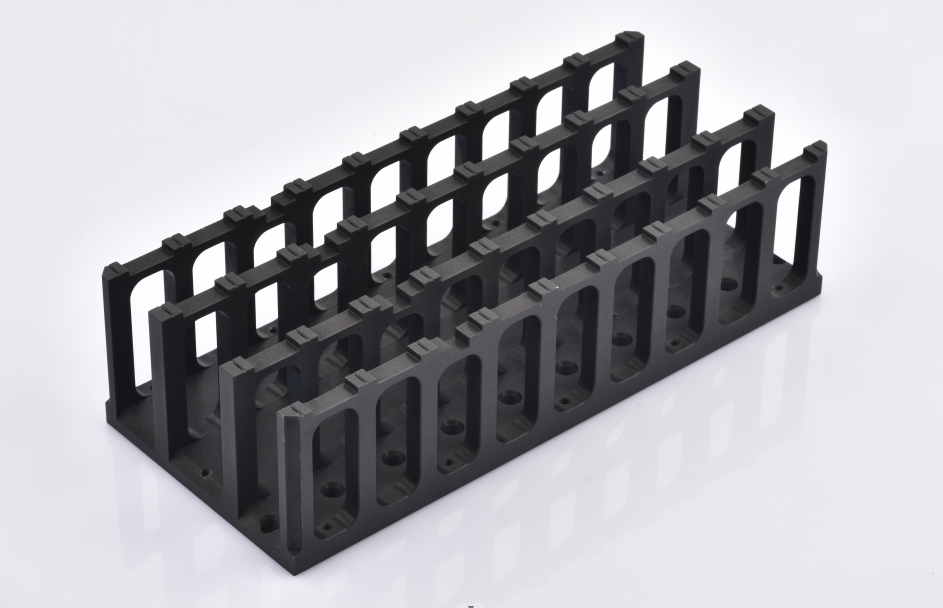

Gallery of CNC machined parts

We machine rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.