In today’s competitive product development landscape, speed matters. At LAIRUN, we specialize in Rapid Plastic Prototyping, helping companies quickly transform their design concepts into high-quality, functional prototypes using precision CNC machining and advanced fabrication techniques.

Our plastic prototyping services are ideal for engineers, designers, and startups seeking quick, low-volume solutions for form, fit, and function testing. Whether you’re developing consumer electronics, medical devices, automotive components, or industrial enclosures, we provide reliable support throughout the prototyping process.

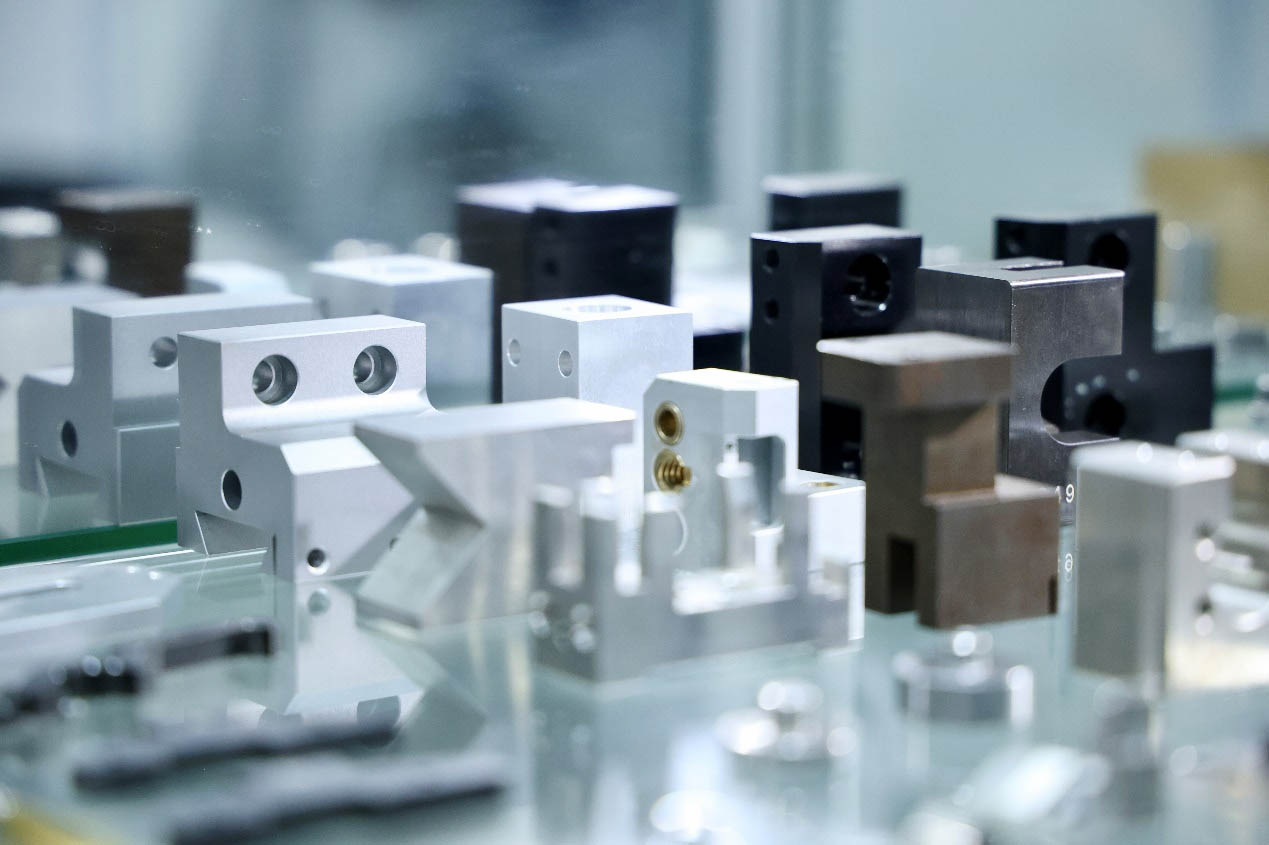

We work with a wide range of engineering-grade plastics including ABS, POM (Delrin), Nylon (PA6/PA66), PC (Polycarbonate), PEEK, and PMMA (Acrylic). These materials offer excellent mechanical properties, durability, and surface finish — essential for validating real-world performance before moving into mass production.

Using high-speed CNC milling, multi-axis machining, and precision turning, we can create complex geometries with tight tolerances and fine details. Our in-house capabilities also include thread cutting, tapping, and surface finishing such as sanding, vapor polishing, and painting. If needed, we offer clear or colored prototypes for presentation models or functional assemblies.

At LAIRUN, we understand the importance of speed-to-market. That’s why we provide fast quoting, short lead times, and responsive engineering support, allowing your team to iterate and refine product designs efficiently. We also support DFM (Design for Manufacturability) guidance to help reduce errors and improve downstream manufacturability.

Whether you need a single prototype or a small batch for performance testing or customer evaluation, LAIRUN’s Rapid Plastic Prototyping services are here to turn your ideas into physical reality — with precision, speed, and flexibility you can count on.

Post time: Jun-24-2025