Elevating Engineering: The Impact of CNC Brass Parts in Modern Manufacturing

Precision Beyond Measure

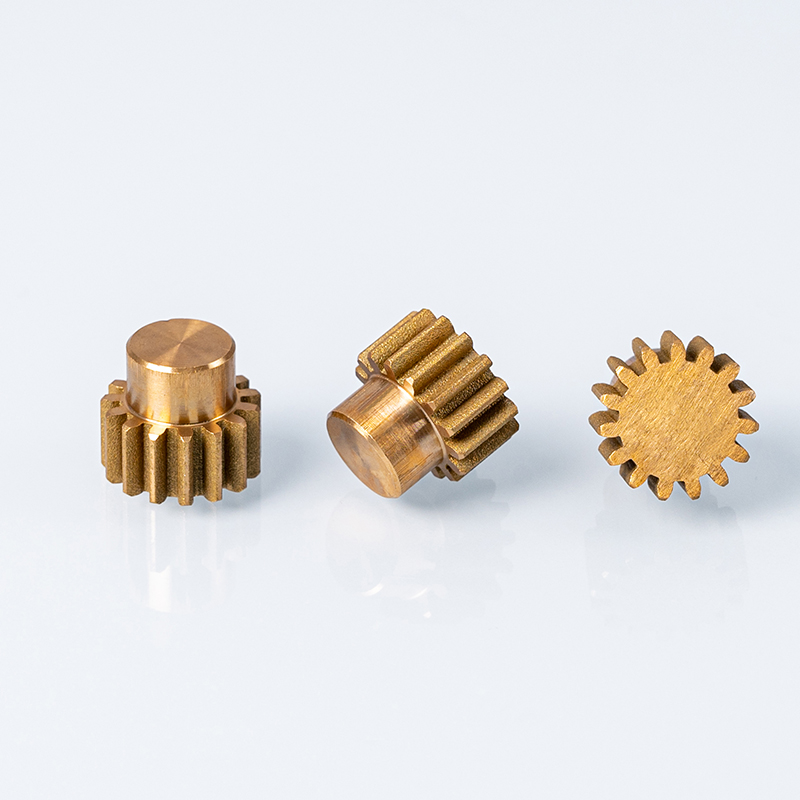

At the core of this revolution is the precision CNC machining of brass parts. The intricacy achieved through CNC machining technology allows for the creation of custom brass components with unparalleled accuracy. From intricate designs to complex shapes, CNC machining ensures that each piece meets the exact specifications, elevating the precision standards in modern manufacturing.

Crafting Custom Solutions

CNC machining brass parts cater to the demand for bespoke solutions in manufacturing. Companies specializing in brass CNC machining services, such as LAIRUN, have become instrumental in providing tailored components for diverse industries. This capability not only streamlines production but also enhances the overall efficiency of manufacturing processes.

Versatility in Brass CNC Machining

The versatility of brass as a material, combined with the capabilities of CNC machining, opens up a myriad of possibilities. From aerospace to electronics, industries benefit from the ability to create intricate and high-quality brass components. CNC machining brass parts are not just a manufacturing process; they represent a gateway to innovation and advancement in engineering.

Driving Quality in Manufacturing

Precision machining is synonymous with quality, and CNC machining of brass parts exemplifies this commitment. The meticulous control afforded by CNC technology ensures consistency in every piece, meeting the stringent quality standards required in modern manufacturing. This, in turn, contributes to the overall reliability of the end product.

Future Forward: Brass Components in the Digital Age

As we navigate the digital age, CNC machining brass parts stand as a testament to the intersection of technology and craftsmanship. The impact of this machining process goes beyond the production floor, influencing the entire ecosystem of modern manufacturing. From optimizing production workflows to pushing the boundaries of design possibilities, CNC machining of brass parts is a driving force in shaping the future of engineering.

In conclusion, the influence of CNC machining brass parts in modern manufacturing is undeniable. Precision, versatility, and quality converge to elevate engineering standards, setting the stage for a future where custom brass components play a pivotal role in innovation across industries.