-

Crafting the Future of Flight: CNC Aerospace Machining and High-Quality Machining Parts

In the dynamic realm of aerospace engineering, precision and quality are paramount. The pursuit of shaping the future of flight relies on the fusion of state-of-the-art technology and the expertise needed to manufacture components that surpass all expectations. This is where CNC aerospace machining, high-quality machining parts, and an unwavering commitment to precision come into play.

-

Medical Precision Machining Meets Innovation with Aluminum Parts

In the dynamic realm of modern healthcare, precision and innovation are the cornerstones of progress. The fusion of medical precision machining and state-of-the-art aluminum components has ushered in a new era in medical manufacturing. This article explores the pivotal role played by CNC machine shops and CNC machining services, coupled with rapid manufacturing, in propelling healthcare innovation to new heights.

-

Delivering Excellence in Aluminum Precision Machining

When it comes to machining aluminum parts, precision and expertise are non-negotiable. At LAIRUN, we take pride in being your trusted partner for all things related to Aluminum CNC Precision Parts. Our commitment to excellence is evident in every aspect of our service, from CNC milling aluminum parts to custom aluminum parts machining.

-

Mastering the Craft: Subcontract Precision Machining Empowered by Inconel Alloys

In the world of precision engineering, where perfection is the ultimate goal, the collaboration between subcontract precision machining and the versatile family of Inconel alloys has redefined the boundaries of what is achievable in manufacturing. This dynamic partnership is making waves across various industries, elevating standards in precision and performance, thanks to a range of Inconel alloys including Inconel 718, Inconel 625, and Inconel 600.

-

The Growing Significance of Aluminum Precision Parts

In the ever-evolving landscape of modern manufacturing, one industry segment is setting new standards and driving innovation like never before. Aluminum precision parts, including aluminum machining parts, and aluminum turned parts, have grown to become a linchpin in various industries, revolutionizing the way we think about precision engineering.

-

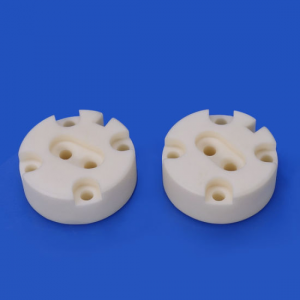

Exploring the Fusion of Precision CNC Milling Parts with Ceramic Excellence

Revolutionizing Manufacturing with Precision CNC Milling Parts

In the fast-evolving landscape of manufacturing, precision CNC milling parts have emerged as the backbone of modern industries. These intricately crafted components, often known as milling machining parts or milling components, are the driving force behind everything from aerospace innovations to electronics advancements. -

Aluminum’s Versatility in Precision Machining Parts

In the realm of manufacturing, aluminum stands as a beacon of versatility, particularly when it comes to precision machining parts. The amalgamation of aluminum’s inherent properties with advanced CNC technology has unlocked a world of possibilities, from machining aluminum parts to creating prototypes with unparalleled precision.

-

Elevating Excellence: Precision Machining of Copper Components for CNC Milling

The convergence of “High Precision Machining Part” with the versatile metal “copper” ignites a transformative journey within the realm of advanced manufacturing. This narrative intricately explores the art and science of precision machining copper components designed specifically for CNC milling, a fusion that not only sets new industry standards but also redefines the boundaries of innovation.

-

CNC Machining In Inconel Parts For Oil And Gas Industry

Welcome to the world of precision engineering and CNC machining services tailored exclusively for the oil and gas industry. At LAIRUN, we take pride in our expertise in delivering top-quality CNC machining parts, rapid services, and precision machining components crafted from robust Inconel materials. With our cutting-edge technology, state-of-the-art facilities, and skilled professionals, we stand as your reliable partner in meeting the most demanding requirements of this critical sector.

-

Carboon Steel CNC Machining Parts——CNC Machining Service Near Me

Carbon steel is an alloy composed of carbon and iron, with carbon content typically ranging from 0.02% to 2.11%. Its relatively high carbon content gives it excellent strength and hardness properties compared to other types of steel. Due to its wide range of applications and relatively low cost, carbon steel is one of the most common types of steel.

-

CNC Acrylic Engraving Cnc Machining Prototypes

Our CNC Acrylic Engraving CNC Machining Services can be used to create a wide range of products, including moldings, fixtures, dies, assemblies, and inserts.

-

Tool Steel CNC machining parts

1.Tool steel is a type of steel alloy designed to be used for a variety of tools and machined components. Its composition is designed to provide a combination of hardness, strength, and wear resistance. Tool steels typically contain a high amount of carbon (0.5% to 1.5%) and other alloying elements such as chromium, tungsten, molybdenum, vanadium, and manganese. Depending on the application, tool steels may also contain a variety of other elements, such as nickel, cobalt, and silicon.

2.The specific combination of alloying elements used to create a tool steel will vary depending on the desired properties and application. The most commonly used tool steels are classified as high-speed steel, cold-work steel, and hot-work steel.”